Conical Agitated Nutsche Filter Dryer

Previous

Next

Product Features Of Conical Agitated Nutsche Filter Dryer

- Filtering, washing, drying and other processes can be completed in the equipment, the whole continuous operation, suitable for sterile and non-sterile pharmaceutical, chemical and other industries.

- It is suitable for the working condition of high solid content, solid phase and liquid phase need to be recovered separately.

- Unique structural design can greatly increase the filtration area, improve filtration and drying efficiency. The lower part of the cone is the discharge port, which is convenient for complete discharging.

- Filter elements can be laid in the cylinder, cone and tank bottom, so that the filtration is completely residue-free.

- The equipment can be configured with heat exchanging devices in all directions, including hollow shaft and double helix with stirring device.

- Double helix with three-dimensional stirring device, stirring effect is outstanding, so that the material in the filtration process is in the state of thin cake.

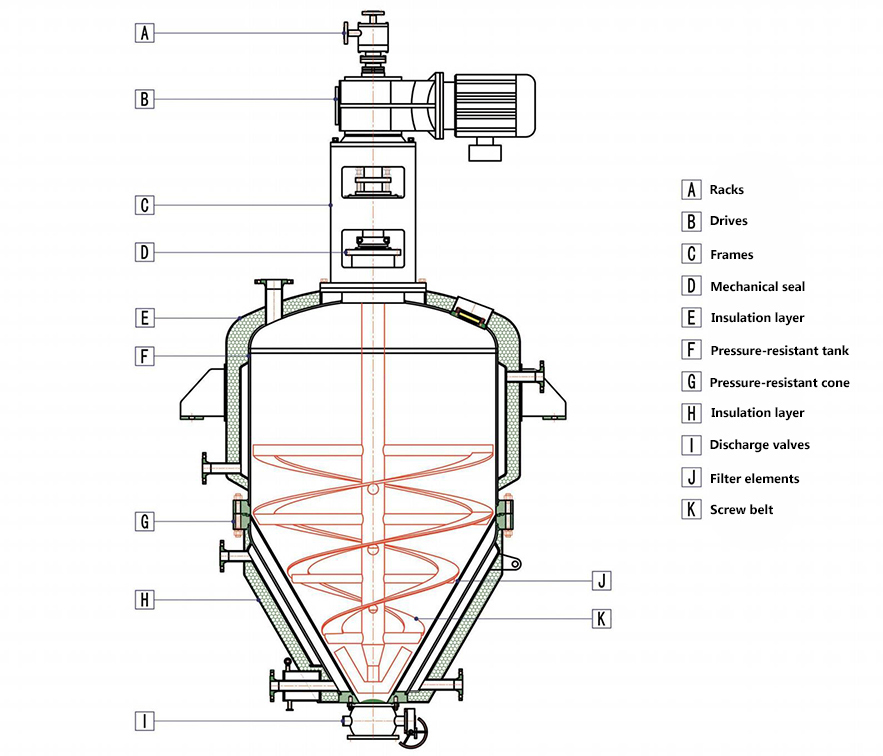

Structural Schematic Of Conical Agitated Nutsche Filter Dryer

Product Functionality Of Conical Agitated Nutsche Filter Dryer

Feeding, filtration, washing, press filtration under pressure or vacuum, vacuum drying, automatic discharging, CIP.

Product Functions Of Conical Agitated Nutsche Filter Dryer

- The Conical Agitated Nutsche Filter Dryer has a range of advanced features that make it a highly effective and versatile piece of equipment for various industrial applications. It allows for complete and efficient processing of materials through several stages including feed, filtration, washing, press filtration under pressure or vacuum, vacuum drying, automatic discharge, and CIP (clean-in-place) cleaning.

- The filter dryer’s conical shape promotes efficient settling of the solids and helps prevent the formation of dead zones within the vessel, thus ensuring a complete discharge of the product. The agitator within the filter dryer keeps the material in suspension throughout the entire process to ensure a consistent and homogenous product quality.

- Furthermore, the filter dryer has the ability to work under both vacuum and pressure conditions allowing for flexibility in the processing conditions. During vacuum drying, the removal of moisture from the material is facilitated by the conical shape and the agitator, which helps to prevent any lump formation and ensures a uniform drying process.

- Finally, the automatic discharge and CIP features of the filter dryer allow for a simple and user-friendly operation while maintaining required standards of cleanliness and hygiene. Overall, the Conical Agitated Nutsche Filter Dryer is a highly effective and efficient piece of equipment for a range of manufacturing processes.

Basic Parameters Of Conical Agitated Nutsche Filter Dryer

| Model | Cone Flltering Area (m²) | Inside Diameter (mm) | Effective Volume (m³) | Cone Volume (m³) | Motor Power (KW) | Net Weight (Kg) | Total Heighi (mm) | |

| CAF-150L | 0.50 | φ600 | 0.15 | 0.045 | 3 | 500 | 2500 | |

| CAF-300L | 0.90 | φ800 | 0.30 | 0.115 | 5.5 | 950 | 2700 | |

| CAF-500L | 1.15 | φ900 | 0.50 | 0.15 | 7.5 | 1500 | 2900 | |

| CAF-1000L | 2.0 | φ1200 | 1.0 | 0.375 | 11 | 2800 | 3200 | |

| CAF-1500L | 2.0 | φ1200 | 1.5 | 0.375 | 15 | 3500 | 3600 | |

| CAF-2000L | 2.5 | φ1400 | 2.0 | 0.60 | 15 | 4800 | 3750 | |

| CAF-3000L | 2.5 | φ1400 | 3.0 | 0.60 | 18.5 | 5800 | 4250 | |

| CAF-5000L | 4.5 | φ1800 | 5.0 | 1.35 | 22 | 7500 | 4800 | |

| CAF-6000L | 5.75 | φ2000 | 6.0 | 1.75 | 30 | 8500 | 5000 | |

Application Industry Of Conical Agitated Nutsche Filter Dryer

The Cylinder Cone Type Filtering Washing and Drying Machine finds widespread application in various industries such as pharmaceuticals, food, pesticides, and chemicals. This advanced equipment is designed to efficiently clean, filter, and dry a variety of materials.

- In the pharmaceutical industry, it plays a crucial role in the production process by ensuring the purity and cleanliness of medicinal substances.

- In the food industry, it is utilized to remove impurities and contaminants from ingredients, ensuring the safety and quality of the final products.

- Similarly, in the pesticide and chemical industries, this machine effectively separates solids from liquids, allowing for precise formulation and production.

With its versatile functionality and reliability, the Cylinder Cone Type Filtering Washing and Drying Machine has become an indispensable asset in these sectors, contributing to improved efficiency and enhanced product quality.

Hot Products

SEARCH

Products

- Filter Cloth

- Filter Cartridge

- PP Folding Filter Cartridge

- PES Folding Filter Cartridge

- PTFE Hydrophilic Folding Filter Cartridge

- PTFE Hydrophobic Folding Filter Cartridge

- Nylon Folding Filter Cartridge

- PALL Large Folding Filter Cartridge

- 3M Large Folding Filter Cartridge

- PARKER High Folding Filter Cartridge

- Large Flow Bag Filter Cartridge

- Melt-Blown Filter Cartridge

- Wire Wound Filter Cartridge

- Activated Carbon Filter Cartridge

- Filtration Apparatus

Get a Quote

We will provide you with the best quality products and the best price according to your order.