Agitated Nutsche Filter Dryer

Previous

Next

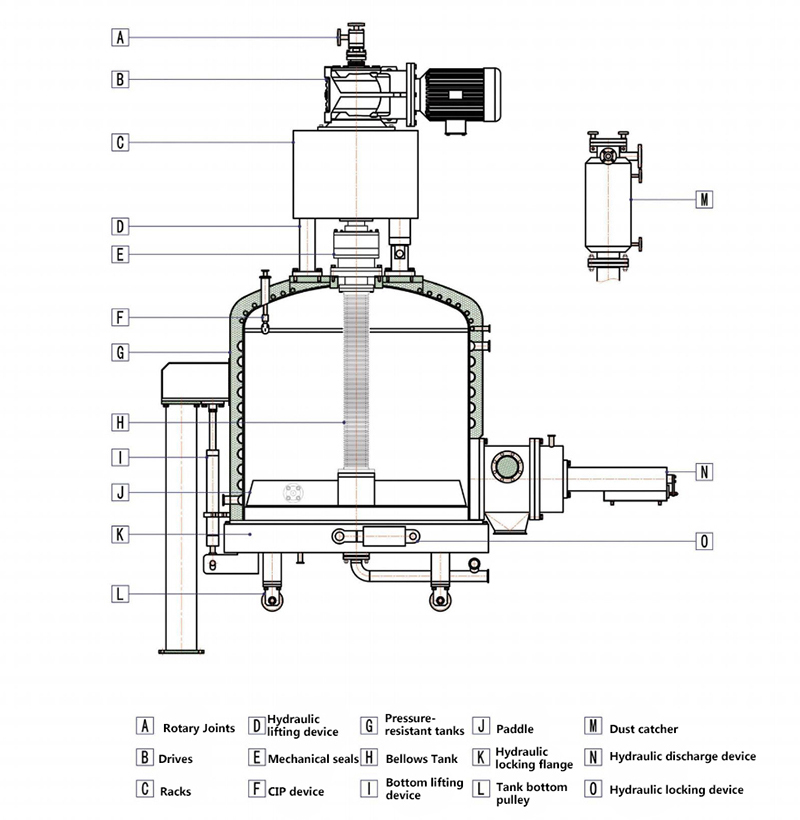

Agitated Nutsche Filter Dryer

Multifunctional filter is to complete the process of mixing, reaction, filtration, cleaning and de-liquefaction, drying, etc. in a closed container. It is characterized by simple structure, simplified process, high production efficiency, no cross contamination, convenient material replacement and high automation degree. The equipment is divided into one-piece The equipment is divided into one-piece type and split-type structure. It mainly consists of driving device, packing seal or mechanical seal, filter tank, stirring system, stirring shaft lifting mechanism, Discharging mechanism, support, field operation knob, main electric control cabinet and hydraulic workstation, and so on.

Structural Schematic Of Agitated Nutsche Filter Dryer

Product Process Of Agitated Nutsche Filter Dryer

Feeding:

Filter:

Solid-liquid separation under vacuum or pressure;

Smoothing:

The agitator scraper rotates in the reverse direction to smooth the cracks on the surface of the filter cake to avoid short circuit of the washing liquid along the cracks;

Slurry Mixing and Washing:

By rotating the spray ball, the cleaning liquid is evenly sprayed in the container, which can realize internal cleaning and filter cake leaching. The filter cake is mixed with the eluent by the lifting agitator, so that the material is fully washed;

Drying:

In a vacuum state,the agitator rotates forward to scrape the filter cake layer by layer, and the equipment heating system uniformly heats the filter cake to accelerate the evaporation of the eluent and the material to be fully dried;

Sampling on line:

During the drying process,the powder sampling valve can be

used for material sampling Inspection;

Automatic Discharging:

After the drying is completed,the agitator rotates forward to scrape loose and push the material to discharge automatically from the discharge port on the side of the equipment;

CIP Online Cleaning and SIP Online Sterilization:

Product Features Of Agitated Nutsche Filter Dryer

- Various processes such as filtration,washing and drying can be completed in the equipment,and the whole process is continuous operation,which is suitable for aseptic and non-sterile pharmaceutical,chemical and other industries;

- It is suitable for working conditions where the solid content is high and the solid phase and the liquid phase need to be recycled separately;

- The design and assembly of the equipment are carried out in strict accordance with the national GMP requirements,fully comply with the requirements of the pharmaceutical production process,and the system is safe,stable and reliable;

- The inner surface of the equipment in contact with the material is flat, smooth,without dead ends,and is easy to clean and disinfect.After mechanical fine polishing or electrolytic polishing,the inner surface of the equipment Ra≤0.35UM,and the outer surface of the equipment Ra≤0.80UM;

- The equipment does not pollute the environment outside the device, and measures such as dust prevention,leakage prevention,heat insulation and noise reductionshall be properly taken.In a fully enclosed working state,the motor,reducer,and lifting device are protected by a cover,and the jacket layer is added with thermal insulation cotton for heat insulation or cold preservation,reducing heat loss and heat exchange with the outside world and impact on the environment;

- The horizontally laid filter material is used to filter thoroughly and without residual liquid.The filter material has a unique sealing structure,which makes it easy and quick to replace the filter material;

- Strictly use safe and reliable explosion-proof electrical appliances, and are equipped with pulleys to eliminate static electricity,safety interlock functions,safety devices,etc.

- Dry double end face mechanical seal,nitrogen protection and cooling,the stirring shaft is equipped with bellows protection;

- Automatic discharging to avoid pollution;

- With online cleaning and online sterilization functions.

Basic Parameters Of Agitated Nutsche Filter Dryer

| Model | Fitering Area (m²) | Inside Diameter (mm) | Effective Volume (m³) | Filter Cake Height (mm) | Blade Lifting Height (mm) | Motor Power (KW) | Net Weight (Kg) | Total Height (mm) | |

| AF-300 | 0.075 | φ325 | 0.050 | 100 | 125 | 0.37 | 600 | 2750 | |

| AF-500 | 0.185 | φ500 | 0.150 | 150 | 200 | 1.5 | 1500 | 3000 | |

| AF-600 | 0.275 | φ600 | 0.200 | 150 | 200 | 2.2 | 1800 | 3200 | |

| AF-800 | 0.50 | φ800 | 0.350 | 150 | 200 | 3 | 2000 | 3500 | |

| AF-1000 | 0.785 | φ1000 | 0.600 | 200 | 250 | 5.5 | 2750 | 3750 | |

| AF-1200 | 1.0 | φ1200 | 1.0 | 200 | 250 | 5.5 | 3750 | 4000 | |

| AF-1600 | 2.0 | φ1600 | 2.0 | 250 | 300 | 15 | 5750 | 4500 | |

| AF-2000 | 3.0 | φ2000 | 3.0 | 300 | 350 | 18.5 | 8250 | 4750 | |

| AF-2400 | 4.50 | φ2400 | 5.0 | 300 | 350 | 22 | 11000 | 4750 | |

| AF-2600 | 5.25 | φ2600 | 6.0 | 400 | 450 | 22 | 12600 | 5000 | |

| AF-2800 | 6.0 | φ2800 | 7.50 | 400 | 450 | 30 | 14000 | 5000 | |

| AF-3000 | 7.0 | φ3000 | 8.50 | 400 | 450 | 30 | 16500 | 5250 | |

| AF-3200 | 8.0 | φ3200 | 10.0 | 500 | 550 | 37 | 18000 | 5500 | |

| AF-3600 | 10.0 | φ3600 | 12.5 | 500 | 550 | 45 | 20000 | 5750 | |

Hot Products

SEARCH

Products

- Filter Cloth

- Filter Cartridge

- PP Folding Filter Cartridge

- PES Folding Filter Cartridge

- PTFE Hydrophilic Folding Filter Cartridge

- PTFE Hydrophobic Folding Filter Cartridge

- Nylon Folding Filter Cartridge

- PALL Large Folding Filter Cartridge

- 3M Large Folding Filter Cartridge

- PARKER High Folding Filter Cartridge

- Large Flow Bag Filter Cartridge

- Melt-Blown Filter Cartridge

- Wire Wound Filter Cartridge

- Activated Carbon Filter Cartridge

- Filtration Apparatus

Get a Quote

We will provide you with the best quality products and the best price according to your order.